Air operated diaphragm pumps

Introduction Plastic Pumps Metal Pumps Sanitary Pumps Special Applications

Having experience in difficult fluid handling applications and in pump manufacture since 1972, we know what you as a customer require from an industrial pump. The air operated diaphragm pumps of Tapflo, have come to meet your expectations, changing many of what you knew about the diaphragm pumps, so far. They are pumps of Swedish origin, made of high quality materials, and built with few components offering reliable operation and easy maintainance.

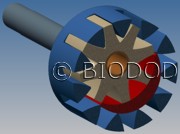

Operation Principle

The Tapflo diaphragm pump is driven by compressed air. The two diaphragms, connected by a diaphragm shaft, are pushed back and forth by alternately pressurising the air chambers behind the diaphragms using an automatically cycling air valve system.

One diaphragm creates a suction action when being pulled back from the housing. The other diaphragm simultaneously transmits the air pressure to the liquid in the housing, pushing it towards the discharge port.

During each cycle the air pressure on the back of the discharging diaphragm is equal to the head pressure on the liquid side. Tapflo diaphragm pumps can therefore be operated against a closed discharge valve with no adverse affect to the life of the diaphragms.

Applications

Paint, print and varnish industry: Transfer of water and solvent based paints, ink, varnish, glue, adhesives and solvents. Transfer, recirculation and blendning of ink in printing industies.

Water treatment: Pumping samples, dosing acids and alkalis for pH-control. Transfer of flocculent, suspensions, chemical reagents and sludges. The pumps are resistant to hydrochloric acid and ferric chlorite, plus many others.

Hygienic applications: Transfer of food products like soup, cream, syrup, milk, yoghurt, flavours, spirit, chocolate, dough, creams, paste, perfumes and toothpaste. Service applications as spraying of cleaning liquid in CIP systems.

Chemical Industry: Transfer of all kind of acids, alkalis, alcohol, solvents and shear sensitive products such as latex and emulsions, as well as chemical waste products.

Pulp and paper industry: Transport of glue, sodium silicate, colour and titanium oxide etc. Bleaching products, sampling and waste water handling.

Surface conditioning: Transport of chemicals from storage tanks, containers and baths, for example in pickling, galvanization and degreasing. Handling of waste products.