Air operated diaphragm pumps

Introduction Plastic Pumps Metal Pumps Sanitary Pumps Special Applications

EHEDG approved aseptic diaphragm pump series

They are designed for sterile applications, primarily in the pharmaceuticals, bio-technology and foodstuffs industries.

They are designed for sterile applications, primarily in the pharmaceuticals, bio-technology and foodstuffs industries.

Tapflo Aseptic series is EHEDG certified, has FDA and USP VI approved materials and conforms to the ATEX directive.

No bacteria growth - Designed for CIP and SIP cleaning - Gentle pumping of sensitive products - Housings made from electro polished stainless steel AISI 316L, Ra 0.8 (standard) or Ra 0.5 on request - Wide range of connection types available: TriClamp, sanitary threads (DIN, SMS) etc - Environmental friendly lube free air valve.

Diaphragms: PTFE (FDA & USP VI), White EPDM (FDA).

USP VI approved Pharmaceutical pump series

They are USP approved (United States Pharmacopoeia) hygienic PE pumps. They are produced to serve the biotech- and pharmaceutical industries in numerous applications.

They are USP approved (United States Pharmacopoeia) hygienic PE pumps. They are produced to serve the biotech- and pharmaceutical industries in numerous applications.

No bacteria growth - Inert and clinical tested materials - Wetted components made from USP VI approved materials - Pump housing with very few components that is extremely easy to maintain - Sanitary clamp connections.

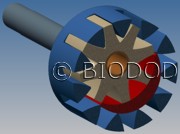

Powder pump series

The Tapflo powder transfer diaphragm pump is an economical and compact solution. It can do the same job as many complex and large powder systems. The compact design also makes the unit portable.

The Tapflo powder transfer diaphragm pump is an economical and compact solution. It can do the same job as many complex and large powder systems. The compact design also makes the unit portable.

Kinds of powder: The powder transfer pump will handle different types of process powders, with specific weight from 80 up to 720 kg/m3 of dry weight. Generally, if the powder does not clump together when you squeeze it in your hand, the Tapflo powder transfer pump can be used successfully. A few examples of common powders are sintering powder, carbon black, resins and silicones.

Capacity: The capacity of the powder transfer is extremely different from one powder to another, depending on the consistency and weight etc.

Safe in EX-zones: The powder transfer pumps are ATEX marked, allowing use in explosion hazardous zones (group IIG/IID, category 2).

Active pulsation dampeners

The active pulsation dampener is the most efficient way to remove pressure variations on the discharge of the pump. The Tapflo pulsation dampener works actively with compressed air and a diaphragm, automatically setting the correct pressure to minimise the pulsations. The pulsation dampener is available for all Tapflo pump sizes and material versions.

The active pulsation dampener is the most efficient way to remove pressure variations on the discharge of the pump. The Tapflo pulsation dampener works actively with compressed air and a diaphragm, automatically setting the correct pressure to minimise the pulsations. The pulsation dampener is available for all Tapflo pump sizes and material versions.